The medical device industry continues to advance with cutting-edge products designed to enhance patient care and healthcare experiences. One critical component of these devices is the choice of materials used in the construction. Polyurethane (PU) foam is a versatile and highly customizable material that has become popular for medical applications.

Open-Cell Polyurethane Foam: Delving Deeper into its Properties

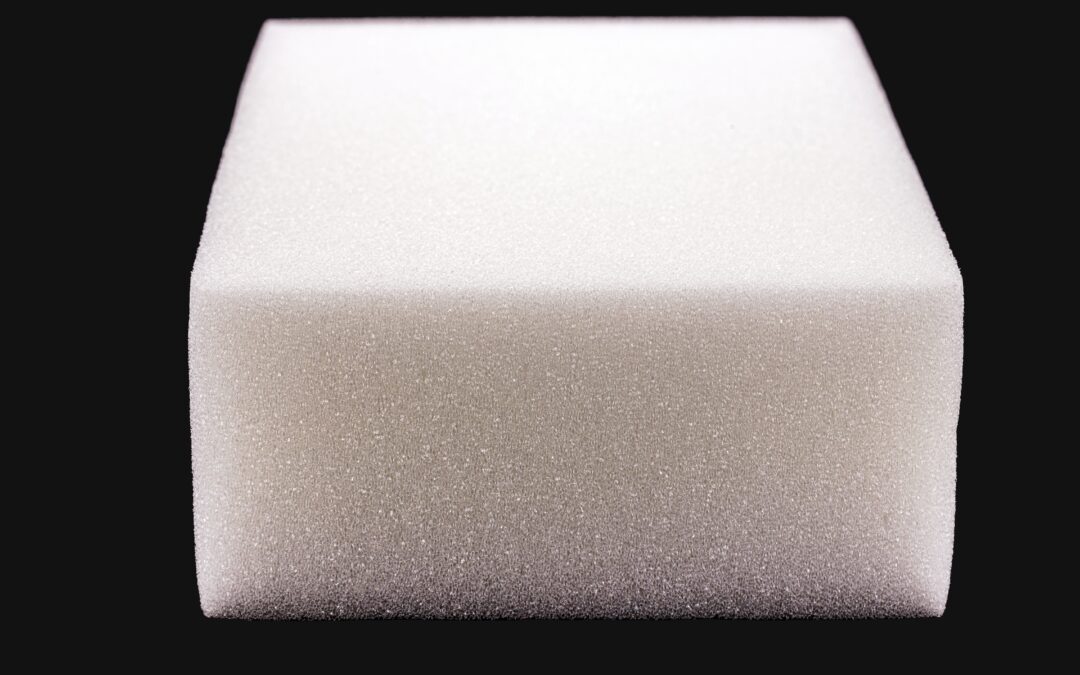

Open-cell foam is characterized by a porous structure in which most of the cells are interconnected, resulting in a lower density and greater flexibility than closed-cell foam. Critical features of open-cell polyurethane foam include:

Softness and flexibility: Open-cell foam is soft and pliable due to having lower density. The softness and flexibility make it suitable for applications requiring cushioning and conformability, such as medical device padding or wound dressings that need to adapt to the body’s contours.

Breathability: The interconnected cell structure allows air to circulate, making open-cell foam breathable and moisture-wicking. This is useful in applications where maintaining a comfortable, dry environment is essential, for example, orthopedic devices or wound care.

Cost-effectiveness: Open-cell foam is generally less expensive than closed-cell foam due to its lower density.

Sound absorption: Open-cell foam can effectively dampen and absorb sound due to its porous structure. This characteristic makes it useful for noise reduction in medical environments, such as earplugs or soundproofing for diagnostic equipment.

Closed-Cell Polyurethane Foam: Exploring its Properties in Detail

Closed-cell foam features a more rigid structure with individual, non-interconnected cells, resulting in a higher density and greater strength than open-cell foam. Key features of closed-cell polyurethane foam include:

Strength and durability: Closed-cell foam has a higher density, making it more resilient and resistant to wear and tear. You may need to focus on strength where the foam has to withstand significant pressure.

Water resistance: Closed-cell foam is impermeable to water due to its non-interconnected cell structure. This characteristic makes it suitable for applications where moisture resistance is crucial, such as in wound dressings or medical devices exposed to fluids.

Insulating properties: The closed-cell structure provides excellent insulation, making it suitable for temperature-sensitive applications. Examples include cold therapy packs or temperature-controlled storage for medications and vaccines.

Chemical resistance: Closed-cell foam is resistant to various chemicals, including those commonly found in medical environments. Having chemical resistance is suitable for devices that may be exposed to harsh chemicals.

Factors to Consider When Choosing the Right Foam for Your Medical Device

To determine the best polyurethane foam type for your medical device, consider the following factors:

Application requirements: The specific needs of your device play a critical role when choosing between open and closed cell foam. These needs may include cushioning, insulation, moister wicking, and chemical resistance. You must consider how the foam will interact with other components of the device and any external factors that may affect the performance of the device.

Regulatory compliance: Your device will need foam that meets regulatory requirements such as biocompatibility and flammability standards. It is crucial to ensure that the safety and efficiency of your device meet all the regulatory standards of the International Organization for Standardization (ISO) and the Food and Drug Administration (FDA).

Manufacturing process: The choice of foam may be influenced by the manufacturing process used to create the device. Some processes may be more suitable for working with certain foam types, so it’s essential to consult with an expert in the field to determine the optimal foam for your device.

Customization Options for Polyurethane Foam

Open-cell and closed-cell polyurethane foams can be customized to meet the specific requirements of your medical device. Some customization options include:

Density: The density, hardness & pore size of polyurethane foam can be adjusted to provide varying support, comfort, and durability in both Polyether & Polyester based formulations.

Additives: Various additives can be incorporated into the foam to enhance its properties, such as antimicrobial agents to reduce the risk of infection, custom colors, hydrophilic properties, or flame retardants.

Shape and size: Polyurethane foam can be easily cut into complex shapes and sizes to fit the unique design of your medical device.

Surface treatments: Surface treatments can be applied to polyurethane foam to modify its properties, such as adding an adhesive backing for easy attachment to other components.

For more information on all the capabilities in customization options for PU foam, click here!

The choice of polyurethane foam for your medical device will significantly impact its performance, comfort, and overall effectiveness. By understanding the differences between open-cell and closed-cell foams and considering the factors outlined in this comprehensive guide, you can make an informed decision that best meets the specific needs of your medical device. With the right foam material in place, you can create a superior product with Foamtec Medical that enhances patient care and contributes to the ongoing evolution of the healthcare industry.

Foamtec Medical is a leading medical device manufacturer that specializes in polyurethane foam. We can customize open and closed cell foam’s properties and will help you determine what foam is right for you. Contact us to learn more about what custom foam solutions are right for you!