CMPs have long been the go-to material for surgical procedures, wound dressings, and diagnostic and interventional procedures, playing a crucial role in all these procedures. While rare, surgery-related complications can mimic more serious conditions, cause unnecessary repeat surgeries, and interfere with healing.

The immune system’s response to CMPs can cause:

- inflammation

- Adhesions

- granulomas

Conversely, foam has emerged as a cleaner and more effective alternative to CMPs, leading to a growing interest in its use in post-operative care. This article examines the reasons behind CMP-related complications and the benefits of using foam as a replacement.

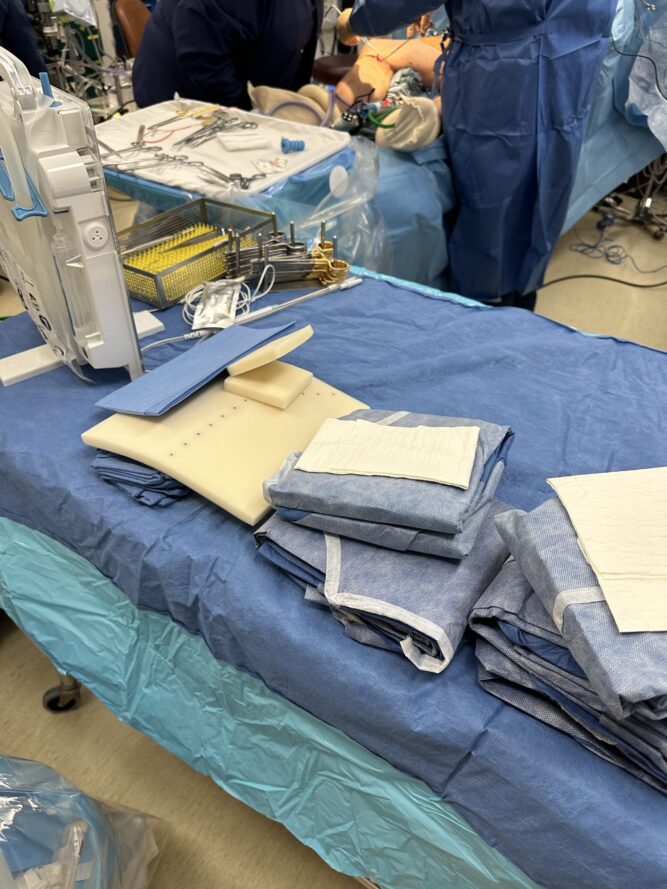

[/et_pb_text][et_pb_image src=”https://foamtecmedical.com/wp-content/uploads/2024/02/SWICKER-in-the-OR-scaled-e1708531219272.jpg” alt=”Syntervention’s SWICKER® Sponge utilizing PU Foam sponge in OR” title_text=”SWICKER in the OR” align=”center” _builder_version=”4.24.2″ _module_preset=”default” global_colors_info=”{}”][/et_pb_image][et_pb_text _builder_version=”4.24.2″ _module_preset=”default” global_colors_info=”{}”]Syntervention’s SWICKER®

[/et_pb_text][et_pb_text _builder_version=”4.24.2″ _module_preset=”default” global_colors_info=”{}”]CMPs: The Past and the Future

CMPs are often used as a generic term to cover a wide range of dressing products. Numerous subcategories differ according to fabric construction or material composition. Non‐woven CMPs replaced woven CMPs because they are less traumatic to the wound and release less lint.

CMPs were used primarily because little else was available, and it was accepted practice that dry wounds healed better. Saline began to be used with CMPs to pack wound cavities, but as an isotonic solution, it drew fluid from the wound into the CMPs, often adhering the CMPs to the wound. This process disguised the adverse effects of the CMPs as the effect was attributed to the solution or, in some cases, antiseptic.

Modern wound dressings grew out of necessity on the battlefield with features to moderate exudation, speed healing, and protect the wound. Today, we have newer materials, such as polyurethane foam, which offer practitioners better and specific product properties such as insulation, permeability, and padding to improve performance.

CMP’s-related Infections and Granulomas

The two most concerning issues related to CMPs are adhesions and granuloma formation.

Adhesions and granulomas are formed by the body’s reactions to the lint from the CMPs left behind in the surgical site or wound. This reaction prolongs the healing process and can mislead practitioners on several differential diagnoses.

The Advantages of Foam as a Replacement for CMPs

The introduction of moisture‐retentive dressings should have facilitated a shift in practice away from the predominant use of CMPs. However, woven CMPs continue to be the most widely used product in wound care. The removal of conventional dry dressings, such as CMPs from colonized wounds, releases significantly greater amounts of bacteria into the air than occlusive dressings. The reasons for the continued use of CMPs are undoubtedly complex and cannot be merely related to unit cost or the perceived paucity of clinical evidence.

Education can play a significant role in adopting new and better wound care. Given the demands on the healthcare practitioner, there are limited opportunities for promoting change. Since nurses are most likely to be changing dressings, it must start there.

In some cases, informed decisions on dressing choices are made by knowledgeable specialists, but the organization in which they work prevents them from asserting their authority over care.

An alternative wound dressing material is Foam dressings. Foam can keep the wound moist, absorb fluid, and protect it. Medical grade sterile foam is a cleaner alternative with less risk of infection and granulomas due to technology that dramatically reduces the presence of particles.

Improved Moisture Control: Foam dressings can maintain an optimal moisture balance in the wound bed. While CMPs can become overly saturated with exudate, leading to a damp environment that encourages bacterial growth. This helps absorb excess fluid while keeping the wound bed moist, which is vital for promoting healing. By controlling moisture levels, foam dressings can reduce the risk of infection and prevent maceration of the surrounding skin.

Reduced Risk of Foreign Body Reactions: Unlike CMPs, foam dressings are less likely to cause granuloma formation. This is because foam is made from materials that are less prone to shedding fibers and causing foreign body reactions. The smooth surface and cohesive structure of foam dressings minimize the risk of fibers becoming embedded in the wound bed, thus reducing the likelihood of granuloma development.

Enhanced Comfort and Protection: Foam dressings are typically softer and more conformable than CMPs, providing better patient comfort during the healing process. They also provide a cushioning effect, which can help protect the wound from external pressure and trauma. Additionally, foam dressings are more resistant to tearing or fraying than CMPs, ensuring the wound remains protected throughout the healing process.

Foamtec Medical: A Leading Manufacturer of Medical Devices Components and Foam Fabrication

As the demand for foam dressings in surgical and wound care applications increases, Foamtec Medical has emerged as a trusted, vertically integrated medical device manufacturer. Foamtec Medical is well-positioned to produce high-quality foam for medical device components.

Foamtec Medical’s expertise in foam fabrication ensures that its products meet the highest quality and performance standards. By working closely with medical professionals and researchers, Foamtec Medical continues to innovate and develop new foam medical device components. Foamtec Medical can fabricate foam for specific medical device needs. Their in-house engineering team works closely with clients to design and manufacture customized foam components that meet precise specifications and requirements.

[/et_pb_text][et_pb_button button_url=”#short-form” url_new_window=”on” button_text=”Contact Us” _builder_version=”4.24.2″ _module_preset=”default” hover_enabled=”0″ global_colors_info=”{}” button_alignment=”center” sticky_enabled=”0″][/et_pb_button][/et_pb_column][/et_pb_row][/et_pb_section][et_pb_section fb_built=”1″ admin_label=”Popup – #short-form” module_id=”short-form” module_class=”popup” _builder_version=”4.19.1″ _module_preset=”default” width=”950px” da_is_popup=”on” da_popup_slug=”short-form” da_disable_devices=”off|off|off” border_radii=”on|12px|12px|12px|12px” box_shadow_style=”preset1″ global_colors_info=”{}” theme_builder_area=”post_content” da_exit_intent=”off” da_has_close=”on” da_alt_close=”off” da_dark_close=”off” da_not_modal=”on” da_is_singular=”off” da_with_loader=”off” da_has_shadow=”on”][et_pb_row _builder_version=”4.19.1″ _module_preset=”default” width=”85%” global_colors_info=”{}” theme_builder_area=”post_content”][et_pb_column type=”4_4″ _builder_version=”4.19.1″ _module_preset=”default” global_colors_info=”{}” theme_builder_area=”post_content”][et_pb_text _builder_version=”4.19.1″ _module_preset=”default” header_3_font=”|700|||||||” header_3_text_align=”center” header_3_text_color=”#283891″ global_colors_info=”{}” theme_builder_area=”post_content”]