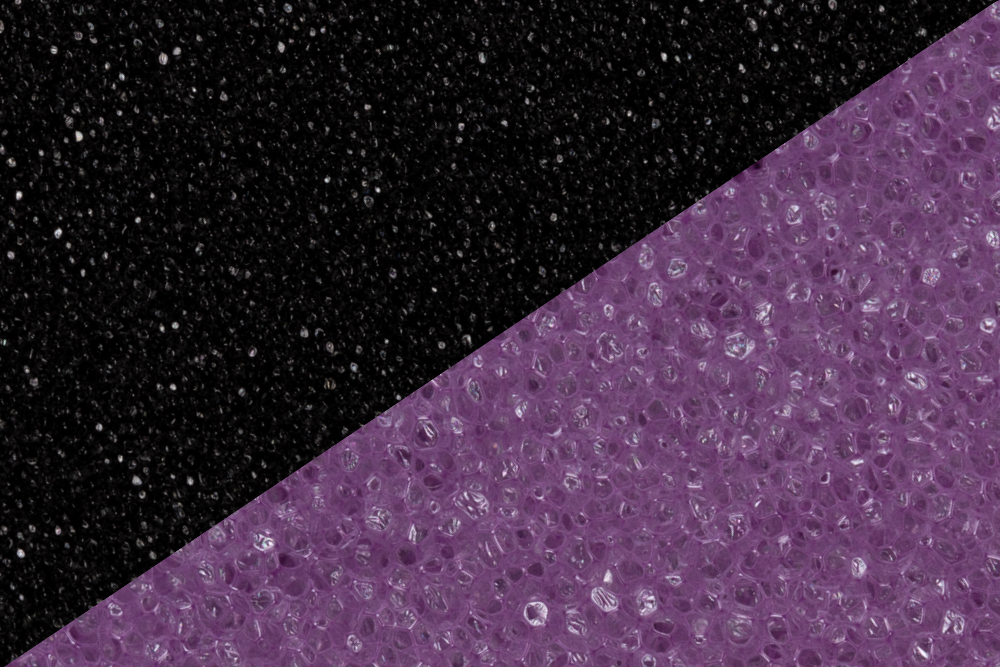

Foams are crucial in various medical applications, providing patient support, comfort, and protection. Two common types of foams used in the medical field are polyether and polyester foams. These materials exhibit different characteristics, including porosity and density, which can significantly impact their suitability for specific medical uses.

Polyether vs. Polyester Foams

Polyether and polyester foams are polymeric materials but have distinct chemical compositions and properties.

Polyether Foams:

- Composition: Polyether foams are made from polyether polyols and are known for their excellent resistance to moisture, humidity, and mildew.

- Durability: They have high tensile strength and are resilient, making them suitable for long-term use.

- Softness: Polyether foams are soft and flexible, providing comfort for patients.

- Biocompatibility: They are generally considered biocompatible and are often used in medical applications where contact with the skin or body is required, such as wound dressings and orthopedic supports.

Polyester Foams:

- Composition: Polyester foams are constructed from polyester polyols and are typically more resistant to chemicals and solvents than polyether foams.

- Durability: They are durable and have good tear resistance, making them suitable for applications where mechanical strength is essential.

- Firmness: Polyester foams tend to be firmer than polyether foams, making them appropriate for cushioning and support applications.

- Sterilization: They can withstand sterilization processes, making them suitable for surgical and medical equipment use.

Porosity and density are key characteristics that affect the performance of foams in medical applications.

Porosity refers to the open spaces or voids within a foam structure.

Controlled porosity is essential in medical foams because it influences the foam’s ability to distribute pressure, provide cushioning, and facilitate air circulation.

Foams with higher porosity are often used in pressure relief applications as they can better distribute the body weight and reduce the risk of pressure sores.

Lower porosity foams, on the other hand, are used in applications requiring water resistance or barrier properties, such as wound dressings.

Density refers to the mass of a foam material per unit volume.

Foam density can affect its support, comfort, and durability in medical applications.

Higher-density foams offer better support and are commonly used in orthopedic cushions and prosthetic devices to provide stability and maintain their shape over time.

Lower-density foams are often employed in applications where comfort is paramount,

The choice between these foams ultimately depends on the specific medical application.

Polyether foams are commonly used in:

- Wound Dressings: Polyether foams are soft and biocompatible. They provide a gentle cushioning effect and conform well to the wound site, promoting healing while minimizing discomfort.

- Pressure Relief Products: Polyether foams with high porosity are used in pressure relief products to help distribute body weight evenly, reducing the risk of pressure sores in bedridden or patients who use wheelchairs.

- Orthopedic Supports: Polyether foams can be found in orthopedic products like knee and elbow pads, lumbar supports, and orthotic shoe insoles. Their soft and flexible nature provides comfort and support to injured or aching body parts.

- Prosthetic Liners: In prosthetics, polyether foams can serve as liners that come in direct contact with the skin. They offer cushioning and comfort to amputees while ensuring good hygiene and biocompatibility.

- Medical Packaging: Polyether foams with lower porosity and moisture resistance properties are used for packaging sensitive medical devices and instruments, protecting them from damage during shipping and storage.

Polyester Foams can be found in:

- Surgical Sponges and Dressings: Polyester foams are often used in surgical sponges and dressings due to their durability and resistance to chemicals and solvents. They can withstand sterilization processes, making them suitable for surgical applications.

- Medical Equipment Padding: Polyester foams are used in medical imaging equipment where mechanical strength and resistance to wear and tear are essential.

- Orthopedic Cushions and Supports: When firmer support is needed, polyester foams are employed in orthopedic cushions, braces, and supports. They provide stability and maintain their shape over time, making them suitable for post-surgery recovery or joint support.

- Medical Filters: Polyester foams with controlled porosity can be used as filters in various medical devices and equipment to trap particulate matter and ensure the purity of fluids and gases.

Porosity and density are critical factors influencing foam performance in medical settings. Controlling porosity allows engineers to tailor foams for pressure relief or barrier functions, while density affects support and comfort. Medical professionals and engineers must carefully consider these factors when selecting foam materials to ensure the best patient outcomes in various medical contexts.

Foamtec Medical’s technical support and R&D team excel at helping develop foam for specific applications. Please get in touch with us today to discuss your next med device project. Once we have an NDA in place, we can assist you in commercializing your idea using the perfect polyether or polyester foam to differentiate your product.