In the ever-evolving world of medical devices, one thing remains constant – the need for durability and reliability. Medical professionals and patients alike depend on these devices for their safety and well-being. This is where Foamtec’s Medical Division comes into play. With our expertise in polyurethane (PU) foam customization, we offer a range of high-performance foams designed to meet the stringent requirements of medical device manufacturers.

Customized PU Foam: More Than Just Foam

A one-size-fits-all approach doesn’t work when it comes to medical devices. Different devices have varying requirements and standards, from cushioning and support to sealing and insulation. Foamtec recognizes the importance of customized solutions and the versatility of polyurethane foam.

Tailored Density and Firmness:

One of the critical aspects of PU foam customization is the ability to fine-tune the foam’s density and firmness. This allows us to create foams with the exact level of cushioning and support required for a specific medical application. Whether it’s for orthopedic devices, wound care products, or medical imaging equipment, Foamtec can design foams that provide the optimal balance between comfort and support.

Enhanced Biocompatibility:

Medical devices often come into direct contact with the human body. Therefore, the biocompatibility of materials is paramount. Foamtec’s PU foams can be customized to meet various biocompatibility standards, ensuring that they are safe and suitable for medical applications.

Antimicrobial and Antistatic Properties:

Some medical devices require foams with specialized features, such as antimicrobial or antistatic properties. Foamtec can engineer foams that inhibit the growth of bacteria or dissipate electrostatic charges, making them suitable for applications in healthcare environments.

Chemical Resistance:

Specific medical applications involve exposure to various chemicals, including disinfectants and cleaning agents. Foamtec’s customized PU foams can be designed to resist these chemicals’ corrosive effects, ensuring the medical device’s longevity.

Open and Closed-Cell Structures:

The cellular structure of a foam is another crucial factor in customization. Foamtec can develop foams with open-cell or closed-cell structures, depending on the device’s requirements. Open-cell foams provide breathability, while closed-cell foams offer higher insulation and protection.

Meeting Regulatory Standards

Strict regulatory standards and guidelines bind medical device manufacturers. Foamtec understands the importance of adhering to these regulations, and our customized PU foams are developed with these standards in mind.

Innovative Solutions for a Variety of Medical Devices

Foamtec’s capabilities in customizing PU foam extend to a wide range of medical devices, including:

Orthopedic Supports and Cushions: Customized foam provides optimal support and comfort for patients using orthopedic braces and cushions.

Wound Care: Our foams can be tailored to create dressings that promote healing and protect against infection.

Medical Imaging: High-performance foam materials can enhance patient comfort during MRI or X-ray procedures.

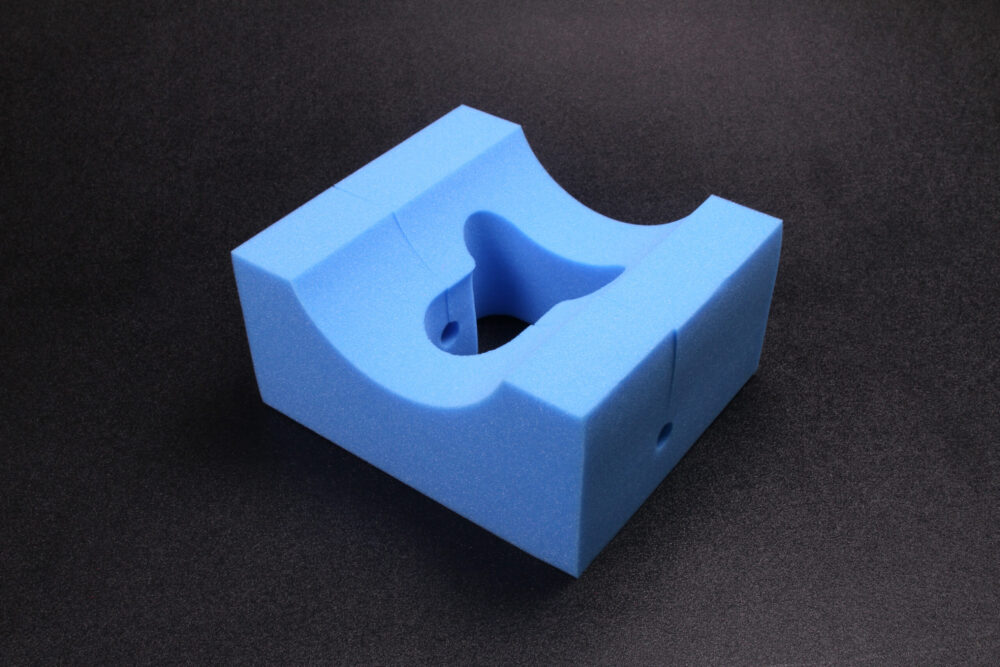

Surgical Instruments: Customized foams can cushion and protect delicate surgical instruments during storage and transportation.

Patient Positioning: Our foams create comfortable and secure patient positioning systems for surgeries and diagnostic procedures.

Pressure Ulcer Prevention: Custom foam solutions help in preventing pressure ulcers among bedridden patients.

Insulation and Sealing: Foams are used in medical equipment to provide insulation and sealing for environmental protection.

In the world of medical devices, one size definitely does not fit all. Foamtec’s Medical Division understands the unique demands of the healthcare industry and offers innovative, customized solutions in the form of polyurethane foams. With the ability to engineer foam materials with various properties and characteristics, we empower medical device manufacturers to create durable, reliable, and high-performance products that meet the industry’s rigorous standards.

If you’re looking to elevate your medical device with custom foam solutions, Foamtec’s Medical Division is here to help. Contact us today to learn more about how our customized PU foams can meet your specific application requirements and exceed your expectations in terms of quality and durability.

[/et_pb_text][et_pb_button button_text=”Contact Us!” _builder_version=”4.23.1″ _module_preset=”default” button_url=”#short-form” hover_enabled=”0″ sticky_enabled=”0″ button_alignment=”center”][/et_pb_button][/et_pb_column][/et_pb_row][/et_pb_section][et_pb_section fb_built=”1″ admin_label=”Popup – #short-form” module_id=”short-form” module_class=”popup” _builder_version=”4.19.1″ _module_preset=”default” width=”950px” da_is_popup=”on” da_popup_slug=”short-form” da_disable_devices=”off|off|off” border_radii=”on|12px|12px|12px|12px” box_shadow_style=”preset1″ global_colors_info=”{}” theme_builder_area=”post_content” da_exit_intent=”off” da_has_close=”on” da_alt_close=”off” da_dark_close=”off” da_not_modal=”on” da_is_singular=”off” da_with_loader=”off” da_has_shadow=”on”][et_pb_row _builder_version=”4.19.1″ _module_preset=”default” width=”85%” global_colors_info=”{}” theme_builder_area=”post_content”][et_pb_column type=”4_4″ _builder_version=”4.19.1″ _module_preset=”default” global_colors_info=”{}” theme_builder_area=”post_content”][et_pb_text _builder_version=”4.19.1″ _module_preset=”default” header_3_font=”|700|||||||” header_3_text_align=”center” header_3_text_color=”#283891″ global_colors_info=”{}” theme_builder_area=”post_content”]Tell Us About Your Project

[/et_pb_text][et_pb_code _builder_version=”4.19.1″ _module_preset=”default” width=”80%” module_alignment=”center” custom_padding=”25px|25px|25px|25px|true|true” border_radii=”on|12px|12px|12px|12px” border_width_all=”1px” border_color_all=”#CCE3E2″ global_colors_info=”{}” theme_builder_area=”post_content”]Oops! We could not locate your form.

[/et_pb_code][/et_pb_column][/et_pb_row][/et_pb_section]