Formulated with inspiration and fabricated with luxurious comfort, Foamtec International’s Medical Division is pleased to announce four new families of foam: EZ™, Prima™, Comfort, and Essential. The Comfort group consists of three distinct foams where the comfort experience is a primary objective for your medical device.

Echo™

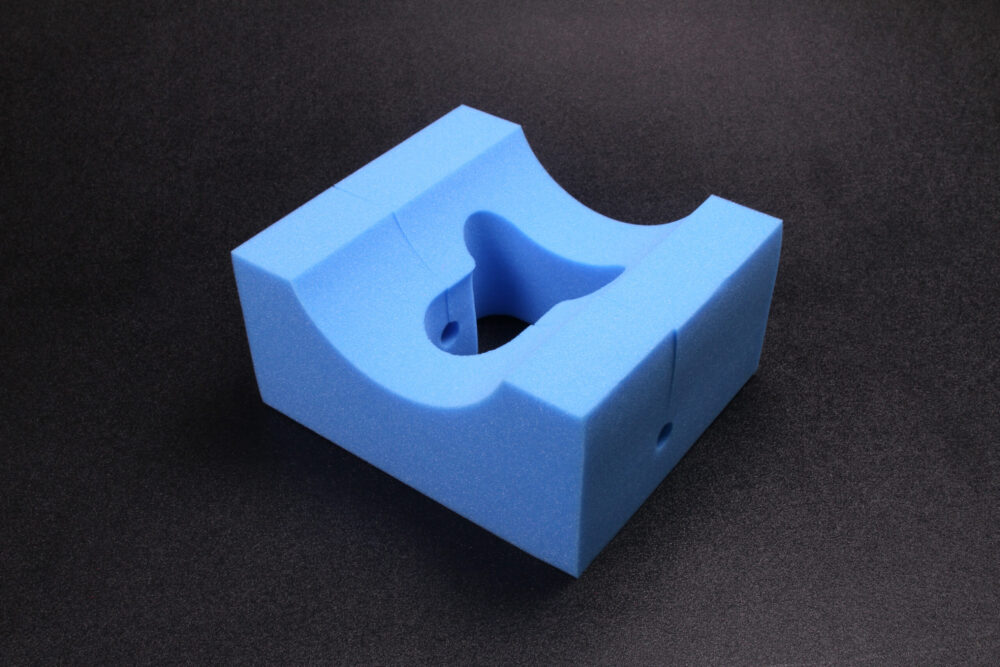

Patient comfort can change the trajectory of the healing process. Polyurethane foam can be used in imaging, surgery, and rehab positioners. The new line of Echo™ foam is ideal for these applications. This foam maintains its shape and can be customized in various shapes to fit every situation.

Imperial™

When you are looking for a top-of-the-line luxury foam, Imperial™ Foam is a magnificent choice. It is porous and highly dense to provide patient support. They are an excellent option for Spa and Wellness Centers, luxury resorts, and private healthcare facilities.

Evo™

Gone are the days of cold steel machines for imaging and simple procedures: thin layers of foam offer a protective layer that increases comfort and minimizes patient apprehension.

Foamtec Capabilities: Transforming Concepts into Reality

But our commitment doesn’t end with foam formulations. Foamtec extends its capabilities to bring your project to new heights. Explore a spectrum of possibilities:

- Laminating: Strengthening bonds for Enduring performance merge layers of different materials seamlessly through our precision laminating process. Heat, pressure, or adhesives are harnessed to create a robust, stable structure. Enhance lifespan and elevate the appearance of your product.

- Adhesives: Our adhesive solutions ensure durability and reliability, securing the success of your project.

- Felting: Achieve a tactile experience that sets your product apart in the market.

- Die Cutting: Precision tailoring for perfect fit precision meets customization with our die-cutting services. Craft products with exacting specifications, ensuring an ideal fit for your application.

- Convolution: Our techniques sculpt innovation, creating products that captivate and perform beyond expectations.

- Vertical & Horizontal Cutting: Engineering precision Our vertical and horizontal cutting-edge processes exemplify precision engineering. We ensure minimal deviation, utilizing advanced machinery and proprietary techniques, delivering unparalleled quality products.

Custom Formulations: Your Vision, Our Expertise

Our team of experienced engineers and material scientists thrives on challenges. Whether you require a foam formulation with specific properties, a unique combination of materials, or tailored performance characteristics, we are ready to turn your vision into reality. From concept to creation, Foamtec is your partner in pushing the boundaries of innovation.

Prototyping Excellence

Before finalizing your custom foam formulation, we offer prototyping services to allow for testing and refinement. This iterative process ensures that the product meets your specifications and performs flawlessly in real-world applications. We prioritize precision and perfection, delivering prototypes that testify to our dedication to quality.

Comprehensive Support: From Concept to Market

Foamtec doesn’t just stop at delivering a custom foam solution; we provide comprehensive support throughout the product lifecycle. Our services include regulatory compliance, testing, and optimization assistance to ensure a seamless journey from concept to market. With Foamtec, you can confidently navigate the medical industry’s complexities.